Court Ordered Real Estate Auction: Ethanol Plant & Grain Malting Operation - Oswego County, NY

134.93 +- Acres with 160,000 +- Sq/Ft. Plant, Rail Yard, Silos, and Malting Operation with German Imported Malt Tanks Located at 376 Owens Road, Volney, NY (Oswego County)

Begins: Tuesday, Apr 29, 2025, 2:00PM EST

Location: 376 Owens Road, Volney, NY 13069

Preview: Tuesday, May 13, Tuesday, June 10 & Tuesday, July 1, 10:00 AM - 2:00 PM.

Registration Closes: Friday, July 11, 1:00 PM.

Begins Closing: Saturday, July 12, 11:00 AM.

Contract Signing: On or Before Monday, July 21, at 4:00 PM.

THIS AUCTION REQUIRES YOU TO SUBMIT A $10,000.00 WIRE TRANSFER DEPOSIT TO SECURE BIDDING PRIVILEGES. PLEASE, ONLY REGISTER AND SUBMIT YOUR BIDDER REGISTRATION APPLICATION IF YOU ARE CAPABLE OF SUBMITTING THE $10,000.00 WIRE TRANSFER DEPOSIT. ONCE YOU SUBMIT YOUR REGISTRATION APPLICATION, WE WILL CALL YOU WITH FURTHER INSTRUCTIONS.

PLEASE CLICK MORE LOT INFO FOR IMPORTANT INFORMATION AND ADDITIONAL PICTURES.

NOTE: All Bids Are Placed at Max Bid.

Categories

|

Next

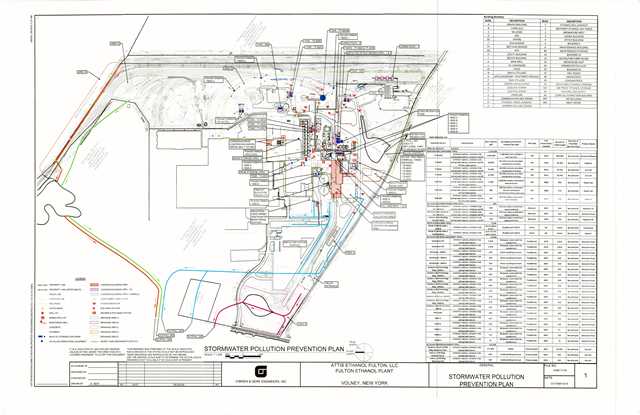

• Ethanol Plant Infrastructure Map

• Ethanol Plant Map

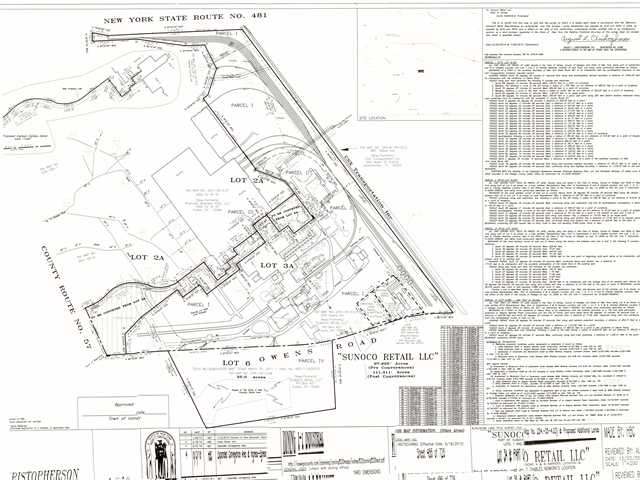

• Aerial Map with Details

• Rail Yard Disclaimer

Closes: Jul 12, 2025 11:00:00 AM EST

No Bids

Minimum Next Bid: $4,700,000.00

bid increments

Login to Bid

Lot Size: 109.93 +- Acres

SBL: 254.00-05-04.03, 254.00-05-04.11, 254.00-05-04.12

Class Code: 710(Manufacturing & Processing), 449(Oher Storage, Warehouse/Distribution Facilities), 714(Light Industrial – Manufacturing & Processing)

Zoning: I-1 - Industrial

Taxes: $844,396.00, $6,182.00, $8,993.00 ($859,571.00 Three Parcel Total) +-

Assessed Value: $8,696,338.00, $96,806.00, $126,263.00 ($8,919,407.00 Three Parcel Total)

Formerly Producing One Million +- Gallons of Ethanol Annually

Scale House: (2) Rice Lake Survivor truck scales-digital read out. (2) hydraulic trobe probes with cameras. (1) MCI auto kicker sampler/moisture analyzer (BCFM). Separate sampling room for truck receiving. Restroom, also additional exterior truckers' restroom.

Grains Receiving: Enclosed truck and (2) rail load out bays. (2) Rail Scales. (2) DDG Load Out Spouts. Separate grains control room with restroom. Backup truck probe (nis).

Grains Storage: (2) 500,000-bushel GSI silos. (1) damaged from fire but potentially salvageable. (1) bin sweep. (1) surge bin.

Milling: (1) Rotex Scalper. (1) Thayer Weigh belt. (3) Roskamp Champion Hammer Mills (1500bu/hr each) with bag houses and Fike Fire Suppression System.

Blending: (1) Scott Mixer. (3) Liquification tanks. (1) Hydrothermal Heater.

Fermentation: (24) Individual fermenters. Chemineer agitators. Goulds 3196 forwarding/mixing pumps. CIP pumps Goulds. Interconnected CO2 header. Tranter heat exchangers.

DDE: Thermokinetics designed distillation pad with mods. Eductor vacuum system. Sulzer pumps. (2) Mole sieve bottles. Swamp cooler with four fans.

CO2: Gardner Denver Spare. Scrubber system. Messer plant on site (customer for CO2 sales).

Centrifuge Building: (5) Z6 Flottweg Decanters. Newer Divine Energy wet cake drag (double drives).

Dryers: (2) Barr Rosin ring dryers. (1) wet cake reclaim hopper.

RTOs: (2) Eisenmann Thermal Oxidizers

Grain storage (final Product/off load): (1) large wet cake pad under roof. (1) enclosed DDG bunker (Typically 8-500 ton piles storage capacity). (1) under cover truck load out spout.

CVOES Corn Oil Extraction: (2) Alpha Laval Separators. (2) Dynamic Heat Exchangers. (2) Corn Oil Storage Tanks. (1) Syrup Feed Storage Tank. (1) Rail Load Out Spout.

Boilers: (2) Victory Package Boilers. Attached utility building with feed water pumps, water treatment for boiler.

Plant Air: (3) Ingersoll Rand Compressors

Cooling Towers on sight: (1) Swamp cooler with DDE pad. (1) Marley tower fermentation/plant. (1) Midwest design new wooden cooler (Never put into service but tied into Fermentation).

Ethanol storage/truck load out: (1) million-gallon final product tank (refurbished by Sunoco). (1) million-gallon blend tank. (1) 38,000-gallon Denaturant tank with floating roof. (1) 2,880 gallon corrosion inhibitor tank. (1) 1,000-gallon diesel tank. (1) 300-gallon gasoline tank. (2) truck load out arms under roof with Toptech meters.

Pump House (water): 1 process water pump. Fire pumps (2 jockey, 1 electric, 1 JD Diesel).

Carbis Rack (Rail Loadout): 4 positions for Ethanol loadout with Toptech meters. 4 positions for CO2 loadout.

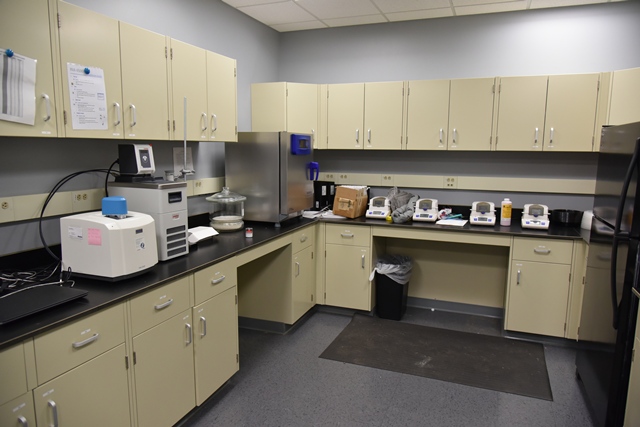

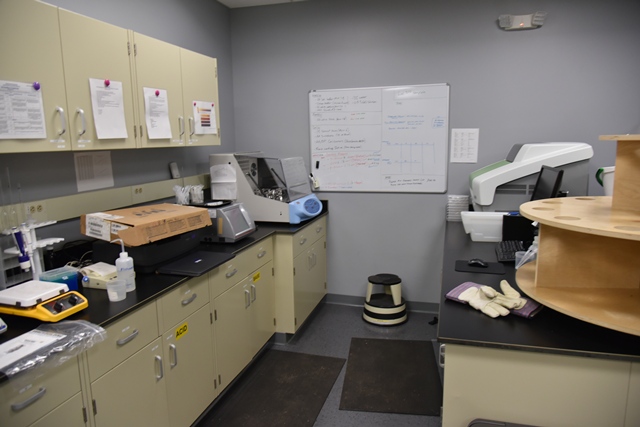

Matlhouse: (Installed Approximately 2017) (4) exterior grain receiving silos. (2) clipper screeners. (2) tempered water tanks. (2) stainless steel steeping tanks. (6) German-Imported 10-ton stainless steel Schultz Rotating Kilns. (6) final product storage tanks. (1) fully automated bagging system (Premier Tech) (bagger, sewing machine, scale, metal detection). (1) robot arm bag palletizer. (2) pallet shrink wrap machines. Clean and dirty lab with all necessary equipment. (2) separate offices. (1) large conference room. (1) restroom. (1) climate-controlled storage warehouse. (2) loading dock doors.

Utilities: 10 meg substation 115kv feed from National Grid. 45 psi natural gas feed into plant from National Grid. (Currently severed. Will need to be restored). 48" water main feed from OCWA. Sewer to City of Fulton (IUP).

Buildings:

Bldg 5 - 46,966 Sq/Ft. 57'7" Ceiling Height

Bldg 6a - 3,611 Sq/Ft. 23'3" Ceiling Height

Bldg 14 - 38,864 Sq/Ft. 26'7" Ceiling Height (Malthouse)

Bldg 25 - 33,858 Sq/Ft. 54'9" Ceiling Height

Bldg 28 - 6,945 Sq/Ft. 95' Ceiling Height

Bldg 4 Second Floor - 20,998 Sq/Ft.

Bldg 91 - 8,500 Sq/Ft. (Boiler Building)

Combined: 159,742 +/- Sq/Ft.

The former Attis rail yard tax parcel is presently in use and occupied by Finger Lakes Railway which presently keeps a locomotive on this parcel and serves several customers at the rail yard including the adjacent Messer C02 plant. It is presumed, but not known, that some owners of parcels located on the remainder of the former Miller Brewery Complex (not involved in this tax auction) may have rights to use or access this rail yard together with the former Attis Facility.

More Details

Lot Size: 109.93 +- Acres

SBL: 254.00-05-04.03, 254.00-05-04.11, 254.00-05-04.12

Class Code: 710(Manufacturing & Processing), 449(Oher Storage, Warehouse/Distribution Facilities), 714(Light Industrial – Manufacturing & Processing)

Zoning: I-1 - Industrial

Taxes: $844,396.00, $6,182.00, $8,993.00 ($859,571.00 Three Parcel Total) +-

Assessed Value: $8,696,338.00, $96,806.00, $126,263.00 ($8,919,407.00 Three Parcel Total)

Formerly Producing One Million +- Gallons of Ethanol Annually

Scale House: (2) Rice Lake Survivor truck scales-digital read out. (2) hydraulic trobe probes with cameras. (1) MCI auto kicker sampler/moisture analyzer (BCFM). Separate sampling room for truck receiving. Restroom, also additional exterior truckers' restroom.

Grains Receiving: Enclosed truck and (2) rail load out bays. (2) Rail Scales. (2) DDG Load Out Spouts. Separate grains control room with restroom. Backup truck probe (nis).

Grains Storage: (2) 500,000-bushel GSI silos. (1) damaged from fire but potentially salvageable. (1) bin sweep. (1) surge bin.

Milling: (1) Rotex Scalper. (1) Thayer Weigh belt. (3) Roskamp Champion Hammer Mills (1500bu/hr each) with bag houses and Fike Fire Suppression System.

Blending: (1) Scott Mixer. (3) Liquification tanks. (1) Hydrothermal Heater.

Fermentation: (24) Individual fermenters. Chemineer agitators. Goulds 3196 forwarding/mixing pumps. CIP pumps Goulds. Interconnected CO2 header. Tranter heat exchangers.

DDE: Thermokinetics designed distillation pad with mods. Eductor vacuum system. Sulzer pumps. (2) Mole sieve bottles. Swamp cooler with four fans.

CO2: Gardner Denver Spare. Scrubber system. Messer plant on site (customer for CO2 sales).

Centrifuge Building: (5) Z6 Flottweg Decanters. Newer Divine Energy wet cake drag (double drives).

Dryers: (2) Barr Rosin ring dryers. (1) wet cake reclaim hopper.

RTOs: (2) Eisenmann Thermal Oxidizers

Grain storage (final Product/off load): (1) large wet cake pad under roof. (1) enclosed DDG bunker (Typically 8-500 ton piles storage capacity). (1) under cover truck load out spout.

CVOES Corn Oil Extraction: (2) Alpha Laval Separators. (2) Dynamic Heat Exchangers. (2) Corn Oil Storage Tanks. (1) Syrup Feed Storage Tank. (1) Rail Load Out Spout.

Boilers: (2) Victory Package Boilers. Attached utility building with feed water pumps, water treatment for boiler.

Plant Air: (3) Ingersoll Rand Compressors

Cooling Towers on sight: (1) Swamp cooler with DDE pad. (1) Marley tower fermentation/plant. (1) Midwest design new wooden cooler (Never put into service but tied into Fermentation).

Ethanol storage/truck load out: (1) million-gallon final product tank (refurbished by Sunoco). (1) million-gallon blend tank. (1) 38,000-gallon Denaturant tank with floating roof. (1) 2,880 gallon corrosion inhibitor tank. (1) 1,000-gallon diesel tank. (1) 300-gallon gasoline tank. (2) truck load out arms under roof with Toptech meters.

Pump House (water): 1 process water pump. Fire pumps (2 jockey, 1 electric, 1 JD Diesel).

Carbis Rack (Rail Loadout): 4 positions for Ethanol loadout with Toptech meters. 4 positions for CO2 loadout.

Matlhouse: (Installed Approximately 2017) (4) exterior grain receiving silos. (2) clipper screeners. (2) tempered water tanks. (2) stainless steel steeping tanks. (6) German-Imported 10-ton stainless steel Schultz Rotating Kilns. (6) final product storage tanks. (1) fully automated bagging system (Premier Tech) (bagger, sewing machine, scale, metal detection). (1) robot arm bag palletizer. (2) pallet shrink wrap machines. Clean and dirty lab with all necessary equipment. (2) separate offices. (1) large conference room. (1) restroom. (1) climate-controlled storage warehouse. (2) loading dock doors.

Utilities: 10 meg substation 115kv feed from National Grid. 45 psi natural gas feed into plant from National Grid. (Currently severed. Will need to be restored). 48" water main feed from OCWA. Sewer to City of Fulton (IUP).

Buildings:

Bldg 5 - 46,966 Sq/Ft. 57'7" Ceiling Height

Bldg 6a - 3,611 Sq/Ft. 23'3" Ceiling Height

Bldg 14 - 38,864 Sq/Ft. 26'7" Ceiling Height (Malthouse)

Bldg 25 - 33,858 Sq/Ft. 54'9" Ceiling Height

Bldg 28 - 6,945 Sq/Ft. 95' Ceiling Height

Bldg 4 Second Floor - 20,998 Sq/Ft.

Bldg 91 - 8,500 Sq/Ft. (Boiler Building)

Combined: 159,742 +/- Sq/Ft.

The former Attis rail yard tax parcel is presently in use and occupied by Finger Lakes Railway which presently keeps a locomotive on this parcel and serves several customers at the rail yard including the adjacent Messer C02 plant. It is presumed, but not known, that some owners of parcels located on the remainder of the former Miller Brewery Complex (not involved in this tax auction) may have rights to use or access this rail yard together with the former Attis Facility.

Location: 376 Owens Road, Fulton NY, 13069

Contact Agent: Fed ID # 14-6002569